-

A basic lithium battery upgrade can start around $1,500 as a DIY project, and more advanced systems can cost more than $15,000 when installed by AM Solar. Complete lithium battery bank projects on RVs and trailers involving solar charging, inverter systems and lithium batteries occasionally exceed $25,000. Expect 10-60 hours of labor plus 1 hour per battery at $130/hr for professional installation.

- Because the voltage of lithium batteries does not change in relation to charge level as much as it does with lead-acid batteries, a BMS (Battery Management System) must be used with lithium batteries to protect them from being overly charged or discharged.

- Lithium batteries will be damaged if charged at freezing temperatures. Because of this, our systems include cold charge disconnect systems (only compatible with Victron Multiplus inverter/chargers).

- If your goal is to run an air conditioner in your Trailer or RV with your lithium batteries, know that one fully charged 200Ah lithium battery will give you about one hour of run time on a typical 15,000 BTU air conditioner, assuming no other loads.

Drop-in Lithium Considerations:

Generally speaking, upgrading from Wet Cell/AGM (Lead Acid) technology to ‘Drop In’ Lithium technology is met with 3 main obstacles.

Does the existing battery footprint provide adequate space needed for the desired Lithium footprint?

This is generally not an issue when we are matching the usable capacity offered by the existing lead-acid system. This becomes more of an obstacle when the customer wants more usable capacity than they currently possess, or when the lead-acid system has split battery locations (this is rare and often only occurs when factory setups are under the chassis, or when a customer has had a second house battery system installed by a 3rd party).

Are the existing lead-acid batteries in an appropriate location?

Because cold and hot temperature regulation is a concern for the overall longevity of lithium batteries (i.e. NO charging below freezing & ideally NO operation beyond 110 degrees Fahrenheit) we are typically more careful about battery placement. Rarely is this possible with the existing battery space, and most often we relocate the system inside the coach. This generally equates to far more labor and materials used, but it varies with each application.

Are the existing charging sources (i.e. Converter or Inv/Chgr. & Alternator) Lithium compatible?

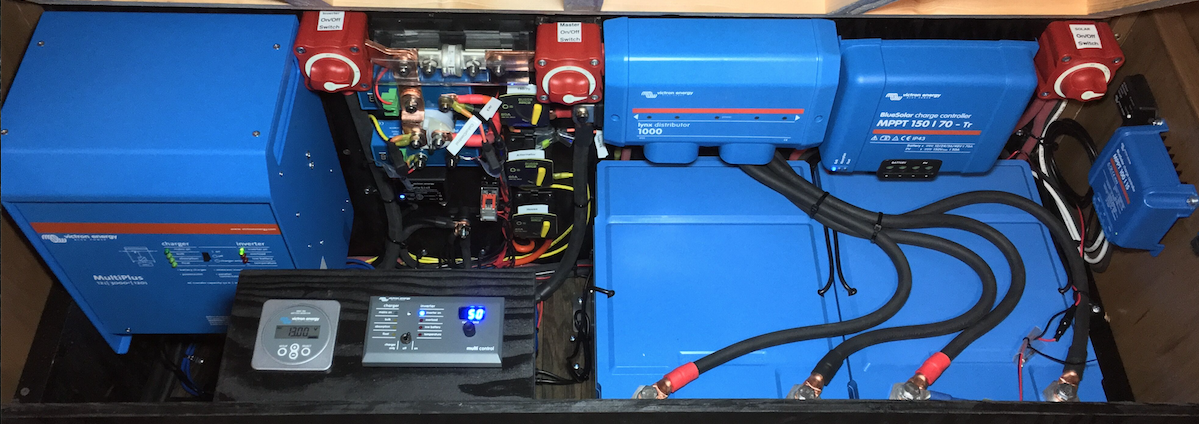

Usually, any factory converter is not compatible and needs to be upgraded, regardless of single or multistage capability. Replacement options include the 30A or 50A Victron Phoenix charger or an Inverter/Charger like the Victron Multiplus. All of which are programmable and lithium compatible, however, some Inverter/Chargers have limited programmability and are not lithium compatible.

The alternator compatibility upgrade requires a swap of the existing alternator isolator/relay for a Cyrix Li-Ct. The complexity of this upgrade is variable depending upon the existing location and its accessibility. Coupled with existing functionality like ‘One-Directional’ or ‘Bi-Directional’ charging as well as ‘Momentary Boost’ capability (i.e. when the coach engine battery dies and the engine can be started from the house battery system), the integration of the Cyrix Li-Ct can be labor intensive.

How this effects installation costs:

Existing battery bay meets obstacle 1 & 2…

· Existing battery removal @ 1-3 hrs. Labor (depends on the size and potential corrosion clean up)

· Lithium battery installation @ 3-6 hrs. Labor (depends on the size and re-cabling needs)

· Misc. Materials @ $100 (could be more or less depending on reusable vs. new cable and cleaning/sealant/other shop materials

Existing battery bay does NOT meet obstacles 1 & 2…

· Existing battery removal @ 1-3 hrs. Labor (depends on the size and potential corrosion clean up)

· Extension of DC connections to new Lithium supportive location @ 4-8hrs Labor

· Lithium battery installation @ 3-6 hrs. Labor (depends on the size and re-cabling needs)

· Misc. Materials @ $200-300 (could be more or less depending on reusable vs. new cable, DC extension cabling/posts/breaker/etc. and cleaning/sealant/other shop materials)

Obstacle 3 has several variable possibilities…

· 30A or 50A Phoenix installation @ 4-6 hrs. Labor (w/ Remote Monitor add 1 hr.) w/ Misc. Materials @ $100-125 (includes DC Brkr. and AC connections)

· Inverter/Charger install @ 14-18 hrs. Labor w/ Misc. Materials @ $100-200

· Cyrix Li-Ct install @ 2-5 hrs. Labor w/ Misc. Materials @ $50-100

Note: Without the coach present, accurate estimating is challenging, and we would always recommend the middle-ground for Labor and Misc. Materials while also informing the customer of a possible cost increase post intake assessment.

“My wife and I have just arrived home after 10 weeks on the road, traveling about 8,000 miles as far as Texas and back thru the Southwest camping all the way in the van. The Victron battery performed flawlessly the entire way and has exceeded even my most fervent expectations. What has been especially gratifying is how quickly it recharges whenever we travel even short distances. What a beautiful system! Thank you so much for the part you played in enabling such satisfaction.”

Frank from Oregon

*The installation of an AMS Lithium battery system for solar panels or anything else is one of the most complex RV power system upgrades available. We can confidently say that nobody else does anything like it and it is very unlikely that anybody else will be able to match our attention to detail, component quality or ability to stand behind our work. These systems are not cheap, and the custom installation is very labor intensive. Our clients purchase these systems because they want the best there is, not because they want something inexpensive. Tremendous demand has us installing one of these systems each week, and every installation is different due to the variety of rigs we work on. Our goal is to have each project brought in on Monday and finished by Friday, but be prepared to have to stay through the following Tuesday. Unforeseen installation challenges may force the project to take longer than expected and our installers have families that need them on the weekends