A client brought in his 2015 Airstream with the following request of AM Solar:

Design an off-the-grid power system (for dry camping and boon-docking) that “runs itself” and requires as little maintenance and oversight as possible both when the trailer is being used and when it is stored.

Specifics:

- Trailer is used for six weeks in the summer, often in shaded campgrounds, 95% of the time without electrical hookups. Stays range from 3-5 nights before moving to next location. Trailer is also used during the other three seasons typically for three-night stays.

- Client has monitored his power usage in the trailer for the last year and a half and concluded that 40-50amp hours is the typical 24 hour energy usage.

- Client doesn’t want to have to bring the batteries to a full charge after each use. Due to not utilizing campgrounds with electrical hook-ups, staying in shaded areas, and often driving short distances between destinations, there is often not enough time to fully recharge batteries via solar and vehicle alternator, especially in the off-season.

- When sun is available, the client wants to utilize every watt possible from their panels to recharge the batteries as they often only travel 2-4 hours before stopping at their next destination.

- Client wants an option to add additional battery capacity and/or solar panels if desired for future energy needs.

To accomplish the above client goals we spec’d one of our Lithium Battery Systems, solar panels, solar charger, and battery charger.

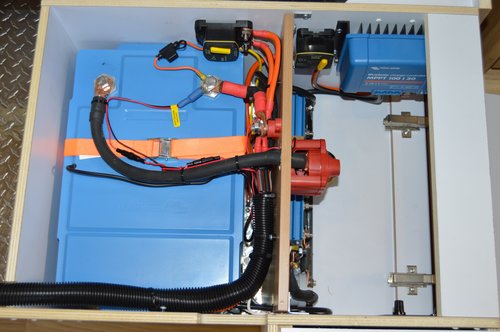

- Because the customer has light AC loads, we chose a 200Ah Essential Lithium Battery system. This will comfortably give them the five nights of camping desired with almost no solar panel input if they are camping under trees in the winter. If the client desires greater battery capacity in the future, this system can be expanded easily with an additional 200Ah bringing the total to 400Ah. Additionally, unlike lead-acid battery based systems, the lithium battery does not need to be recharged to 100% after each use.

- Due to the potential for tree cover, we chose 400W of solar panels to give the client ample solar charging capacity.

- We chose a 50A charger to maximize all available power (solar and vehicle alternator) to recharge the batteries as quickly as possible.

- We chose a three-stage battery charger so that the client can leave the trailer plugged in when stored without having to be concerned about the batteries being charged correctly.

Equipment Added:

4x SP100W Panels

1x Roof C-Box

2x 15.5″ Tilt Bar Sets

1x SunRunner Victron MPPT 30A

1x Victron MPPT Control

1x 200Ah Essential Battery Bank

1x Phoenix Charger 12/50

1x Phoenix Charger Control/Monitor

Because the BMS on the Essential system acts on the negative side of the batteries (ground control), the negative (or chassis) from the tow vehicle with the alternator is at a slightly different voltage than the negative output of the lithium system. This creates a design challenge since shorting the negative output of the lithium system to the tow vehicle chassis would damage the BMS.

In a van conversion or coach, the issue of having two different negatives is easily resolved by routing the output of the lithium battery through the Orion 12/12 DC converter. The negative output of the Orion converter can then be tied to the chassis and all positives for the DC loads get re-routed to the positive output of the Orion. If the total DC load is more than 30A, multiple Orion converters can be connected in parallel. Inverters, or anything else that can have their negative isolated from the chassis will just connect directly to the output of the lithium battery system without going through the Orion converter.

In trailers, the issue of having two different negatives is solved differently. In this situation, the Orion converter goes on the input side of the lithium system, thus isolating the trailer from the tow vehicle’s chassis. When this is done, the Orion converter has to be modified so it’s output voltage is 14.2V instead of the factory 12.0V. This is accomplished by carefully tuning a potentiometer inside the converter that is accessible when the cooling fan is removed. This design will limit alternator charging current to 30A, but it will protect the BMS from having it’s input and output short circuited.